Autoclaves

Autoclaves are vital in healthcare, microbiology, and material science and crucial in sterilizing equipment and supplies. Using high-pressure saturated steam, autoclaves eliminate all microbial life forms, including spores and viruses. This introductory section explores what autoclaves are, their importance in various industries, and how they differ from other sterilization methods.

Key Takeaways

- Understanding the operational principles of autoclaves and how they achieve sterilization.

- Insights into the various types of autoclaves and their specific applications.

- Maintenance tips to ensure longevity and optimal performance of autoclaves.

- Common issues and troubleshooting methods for effective problem-solving.

What is an Autoclave?

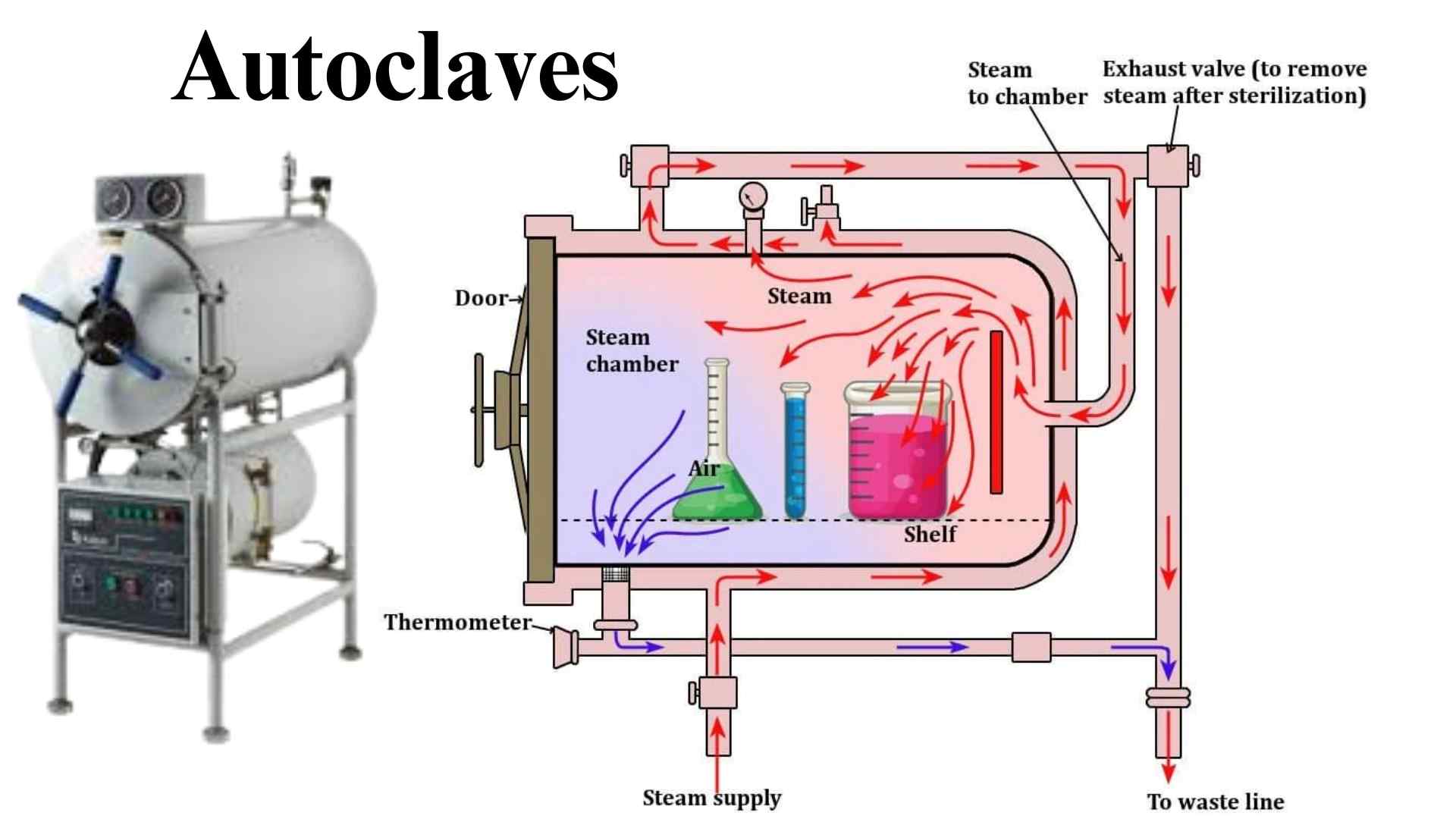

Definition and Basic Principles

An autoclave is a pressure chamber used to carry out industrial and scientific processes requiring elevated temperature and pressure different from ambient air pressure. Autoclaves sterilize equipment by subjecting it to high-pressure saturated steam at 121 °C (250 °F) for 15–20 minutes, depending on the size of the load and its contents. The principle behind autoclaving is the ability of steam to penetrate materials, effectively killing all microbes, spores, and viruses.

Historical Development of Autoclaves

The development of the autoclave has its roots in the 19th century when French microbiologist Charles Chamberland, a colleague of Louis Pasteur, invented the first steam sterilizing machine in 1879. This invention was motivated by the need for more reliable sterilization methods in medical environments, improving on previous practices like open flaming or boiling water, which were less effective against spores.

Comparison with Other Sterilization Methods

Unlike dry heat, which uses high temperatures to sterilize objects over extended periods, autoclaves use steam under pressure to achieve sterility quickly and effectively. Other methods include chemical sterilization, irradiation, and filtration, each suitable for different materials and specific applications. Autoclaves stand out because they can quickly and uniformly penetrate materials, making them ideal for medical instruments, laboratory ware, and other materials that can withstand moisture and heat.

Types of Autoclaves

Gravity Displacement Autoclaves

This type of autoclave is the most basic form of steam sterilizer. It allows steam to enter and displace the cooler air down and out of the chamber through vents. This method is suitable for most general laboratory applications involving liquids and solids where air entrapment is minimal.

Pre-vacuum Autoclaves

Pre-vacuum autoclaves create a vacuum in the chamber to remove air before introducing steam. This method is particularly effective for sterilizing complex items like surgical instruments with lumens, as it ensures that steam penetrates every area. The process is faster and more efficient than gravity displacement, making it preferred in high-volume settings.

Bulk Autoclaves

Designed for large-scale sterilization applications, bulk autoclaves can handle substantial volumes of goods at a time, making them ideal for industrial applications. They are used in the pharmaceutical and food industries to sterilize large batches of products or materials, ensuring compliance with regulatory standards and maintaining product safety and quality.

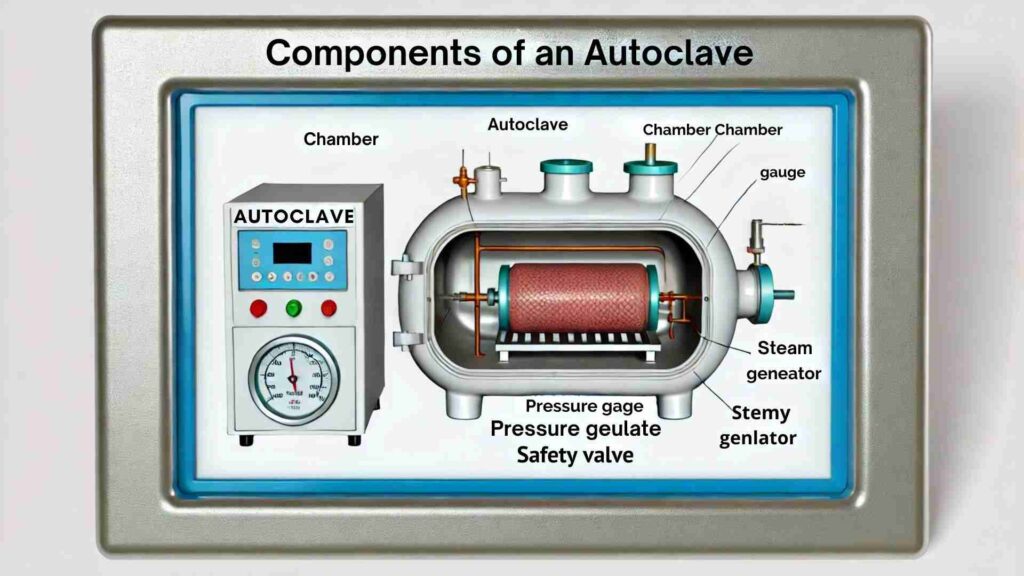

Components of an Autoclave

Chamber and Door

The chamber is the core component of an autoclave, where the sterilization process occurs. It’s typically made from robust materials such as stainless steel to withstand high pressure and steam temperature. The equally sturdy door is designed to form a tight seal to maintain the necessary environment inside. It often has locking mechanisms that prevent opening during operation to ensure safety.

Control Systems

Autoclave control systems manage the sterilization cycle’s temperature, pressure, and duration. These may be simple mechanical systems or complex digital interfaces providing precise control and monitoring capabilities. Modern autoclaves feature programmable settings, allowing users to customize cycles for different instruments and materials.

Safety Features

Safety features are critical in autoclaves to prevent accidents and ensure the device operates within safe parameters. Common safety features include pressure-release valves, door interlock systems to prevent opening under pressure, and alarms for temperature and pressure deviations. These features help to mitigate risks and ensure the safe operation of the autoclave.

Operating an Autoclave

Step-by-Step Procedure

- Preparation: Ensure all items are properly cleaned before sterilization.

- Packing and Loading: Loosely pack the items in suitable containers and load them into the autoclave, ensuring they do not touch the chamber walls.

- Setting the Cycle: Select the appropriate cycle based on the items’ material and contamination level.

- Starting the Cycle: Close the door securely and start the sterilization cycle.

- Monitoring: Monitor the cycle progression through the control system.

- Completion: Once the cycle is complete, allow the autoclave to depressurize and cool down before opening the door.

- Unloading: Remove the items once safely handled, checking for any signs of improper sterilization.

Safety Protocols

- Never override safety features such as door locks and pressure valves.

- Regularly check safety systems for proper functionality.

- Always wear protective equipment such as gloves and face shields when loading or unloading the autoclave.

- Follow the manufacturer’s instructions for the operation to ensure compliance with safety standards.

Best Practices for Loading the Autoclave

- Do not overcrowd: Ensure enough space around items for steam to circulate.

- Use compatible materials: Not all materials are autoclavable; check compatibility to avoid melting or damage.

- Place items correctly: Orient items to facilitate steam penetration and drainage.

- Use proper trays and containers: These should be designed to withstand the conditions inside autoclave use.

By adhering to these guidelines and understanding the components and operations of an autoclave, users can ensure efficient and safe sterilization.

Applications of Autoclaves

Medical and Surgical Tools

Autoclaves play a critical role in the healthcare industry by sterilizing medical and surgical tools. These devices ensure that instruments such as scalpels, forceps, and surgical drapes are free from bacteria, viruses, and other pathogens before they are used in medical procedures. The reliability of autoclaves in providing a sterile environment is essential for preventing infections and maintaining patient safety.

Laboratory Research

Autoclaves are indispensable for sterilizing equipment, media, and biological waste in laboratory settings. Laboratories dealing with microbiology, biochemistry, and molecular biology rely on autoclaves to maintain the sterility of culture media, glassware, and instruments. Autoclaves also play a crucial role in decontaminating hazardous biological waste, ensuring that it can be safely handled and disposed of without risking contamination or infection.

Industrial and Manufacturing Processes

Beyond healthcare and research, autoclaves are also used in various industrial and manufacturing processes. In producing certain goods, such as rubber, composites, and ceramics, autoclaves are utilized to cure materials under high pressure and temperature, enhancing their physical properties. In the food industry, autoclaves sterilize food products and packaging, extending shelf life and ensuring consumer safety. The versatility of autoclaves makes them a valuable tool in numerous industrial applications.

Maintenance and Care

Routine Maintenance Checks

Regular maintenance checks are essential for an autoclave’s optimal performance. These checks typically involve inspecting the seals, gaskets, and pressure valves to ensure they are in good working condition. The water and steam systems should also be examined for any signs of leaks or blockages. Performing routine maintenance checks helps prevent unexpected breakdowns and ensures that the autoclave operates efficiently.

Cleaning and Upkeep

Proper cleaning and upkeep are vital to extending the lifespan of an autoclave and maintaining its effectiveness. After each use, the chamber should be cleaned to remove any residue or contaminants that could compromise the sterilization process. Regular descaling of the water system is also important to prevent mineral buildup, which can affect the autoclave’s efficiency. Following a consistent cleaning schedule helps keep the autoclave in optimal condition and reduces the risk of contamination.

Long-term Maintenance Strategies

Long-term maintenance strategies involve more in-depth inspections and servicing, often performed by trained technicians. This may include recalibrating sensors, replacing worn-out components, and upgrading software to ensure the autoclave complies with the latest standards and regulations. Investing in long-term maintenance not only prolongs the life of the autoclave but also ensures it continues to perform at its best, providing reliable sterilization for years to come.

Troubleshooting Common Issues

Identifying Common Failures

Autoclaves are complex machines that can encounter various issues over time. Common failures include temperature inconsistencies, pressure fluctuations, and mechanical malfunctions. These issues can compromise the sterilization process, making it crucial to identify and address them promptly. For example, incomplete sterilization can occur if the autoclave fails to reach or maintain the necessary temperature and pressure levels. Other common issues include water leaks, door seal problems, and error messages related to sensor faults.

Solutions to Typical Problems

Addressing common autoclave issues requires a systematic approach. Temperature inconsistencies can often be resolved by calibrating the temperature sensors and ensuring the heating elements function correctly. Pressure issues might stem from leaks in the chamber or faulty pressure valves, which can be fixed by replacing damaged components. Water leaks often occur due to worn-out gaskets, which should be inspected and replaced regularly. For mechanical malfunctions, such as door seal problems, lubricating the door seal and checking for debris in the locking mechanism can help restore proper function.

When to Call a Professional

While many autoclave issues can be resolved with routine maintenance, some problems require the expertise of a professional technician. If troubleshooting steps do not resolve the issue, or if the autoclave displays persistent error codes, it is advisable to contact a certified service provider. Additionally, if the autoclave experiences electrical failures or significant mechanical breakdowns, professional intervention is essential to ensure the machine is safely repaired and returned to optimal working condition.

Advancements in Autoclave Technology

Innovations in Sterilization

Autoclave technology has seen significant advancements in recent years, particularly in the area of sterilization methods. Innovations such as plasma sterilization and low-temperature sterilization have expanded the capabilities of autoclaves, allowing for sterilizing heat-sensitive materials. These technologies utilize gases like hydrogen peroxide and peracetic acid in combination with vacuum processes to achieve sterilization without the need for high temperatures, making them suitable for delicate instruments and materials that traditional autoclaves cannot handle.

Energy Efficiency and Sustainability

Modern autoclaves are increasingly designed with energy efficiency and sustainability in mind. Advances in insulation, heat recovery systems, and water-saving technologies have reduced their environmental impact. Energy-efficient models consume less power and water while maintaining high sterilization standards. Additionally, developing autoclaves with reduced cycle times helps lower energy consumption, making them more cost-effective and environmentally friendly.

Future Trends in Autoclave Design

The future of autoclave design will likely focus on further improving efficiency and usability. Trends such as automation, remote monitoring, and smart technology integration are expected to play a significant role in the next generation of autoclaves. These features will allow users to monitor autoclave performance in real time, receive alerts for maintenance needs, and automate sterilization cycles to minimize human error. Furthermore, advancements in materials science may lead to the development of lighter, more durable autoclave chambers, enhancing portability and ease of use.

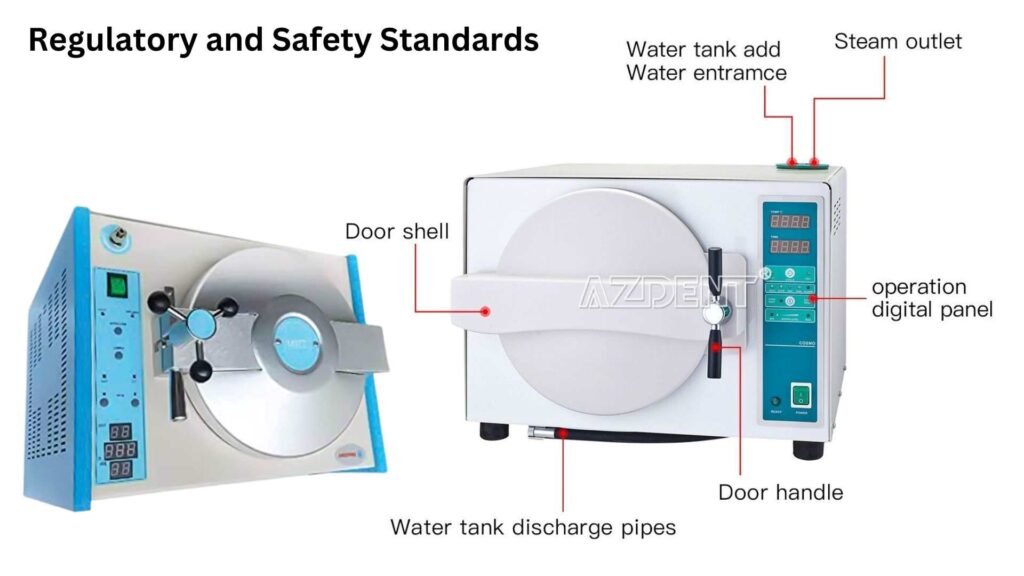

Regulatory and Safety Standards

International Sterilization Standards

Autoclaves used in medical, research, and industrial settings must adhere to stringent international sterilization standards. These standards, such as ISO 17665, outline the requirements for moist heat sterilization processes. Compliance with these standards ensures that autoclaves effectively eliminate all forms of microbial life, providing a reliable and consistent sterilization process. Manufacturers and operators must ensure that their autoclaves meet these standards to guarantee the safety and efficacy of the sterilization process.

Compliance and Certification

Compliance with regulatory standards is essential for the legal operation of autoclaves, especially in healthcare and laboratory settings. Certification bodies, such as the FDA (Food and Drug Administration) in the United States and CE marking in Europe, provide certification to autoclaves that meet specific safety and performance criteria. Regular inspections and audits are conducted to ensure ongoing compliance with these regulations, and any non-compliance can result in penalties or the shutdown of operations.

Safety Regulations and Guidelines

Operating an autoclave requires adherence to strict safety regulations and guidelines to prevent accidents and ensure user safety. These guidelines cover aspects such as proper loading techniques, maintenance schedules, and the use of personal protective equipment (PPE). Safety regulations also mandate the installation of emergency shut-off mechanisms, pressure relief valves, and other safety features to protect operators from potential hazards. Autoclaved personnel often require Training and certification programs to ensure they understand and follow these safety protocols.

Conclusion

Final Verdict

Is using an autoclave the best method for sterilization? Based on extensive research and industry standards, it is highly recommended that autoclaves be utilized for sterilization across medical, laboratory, and industrial applications. Autoclaves offer reliable, effective, and safe sterilization, ensuring that all microbial life, including the most resistant spores, is thoroughly eliminated.

Recommendations

For professionals and institutions seeking optimal sterilization results, investing in high-quality autoclaves that meet international standards is crucial. Regular maintenance and adherence to safety protocols will ensure the autoclave’s longevity and efficacy. Additionally, consider advancements in autoclave technology that enhance efficiency and sustainability, always consulting with certified technicians for the best operational practices.

FAQs about Autoclaves

Q1: What is an autoclave used for?

An autoclave sterilizes equipment and materials by applying high-pressure steam, effectively killing all forms of microorganisms, including bacteria, viruses, and spores.

Q2: How does an autoclave work?

An autoclave generates steam under high pressure, penetrating the items inside the chamber. The combination of high temperature and pressure effectively sterilizes the materials.

Q3: Can all materials be sterilized in an autoclave?

Not all materials can be autoclaved. Heat-sensitive items like certain plastics, electronics, or delicate instruments may be damaged by the high temperature and pressure.

Q4: How often should an autoclave be maintained?

Regular maintenance is crucial for autoclaves. Routine checks and cleaning after each use are recommended, with more thorough maintenance, including calibration, performed at least annually by a qualified technician.

Q5: What should I do if the autoclave shows an error message?

If your autoclave displays an error message, refer to the user manual for troubleshooting steps. If the issue persists, contact a certified technician to diagnose and resolve the problem.